Craft Malt Begins Here at Our Malt House

Two Track Malting has built a world class malting facility constructed with the future in mind. Using a highly efficient malting system paired with an automated cleaning and packaging line this facility is taking Two Track Malting to the next level in the craft malt industry.

Steeping

Steeping is the first stage of the malting process and begins by loading cleaned grain into a steep tank which allows the grain to be submerged. During the steeping process grain is submerged in water with the primary goal of increasing the moisture content of the grain from 12% to 40-44%. This process takes 1-2 days in which the grain is submerged, drained and repeated until the correct moisture content is achieved. Steeping starts the growth process and a visual indicator of properly steeped grain is to see the chit, or rootlets, start to emerge from the grain. Once chitting begins it is time to move the grain into the germination stage.

Germination

Germination is the next stage in the malting process where chitted grain is transferred into our Germination Kiln Vessel or GKV. Germination allows for the development of malt enzymes which modify the structure of the grain’s endosperm by breaking down the cell walls and protein matrix, this process is also known as modification. The enzymes produced during germination are needed to break down the starch for the brewer or distiller during the mashing process. Germination takes 3-5 days and once the grain has reached optimal modification it is ready for the kiln.

Kilning

Kilning is the final step in the malting process and turns the modified grain into malt. The specific type of malt being produced will determine how long the grain is left in the kiln. The kiln is essentially a large oven which uses heat to dry out the grain. This process gives malt its flavor and color. After about 24 hours we have finished malt which is cleaned, packaged, and ready to be made into your craft beer or spirits.

World's First

Two Track Malting partnered with Buhler who is the world leader in malting equipment. We decided to go with Buhler’s Rimo Malt system as it allowed us to set the stage for future growth. We are the world’s first using this type of malting equipment however Buhler has a strong history of developing much larger malting systems. We knew their expertise would allow us to still remain craft while using the latest technology and precision to deliver the best products that we possibly can.

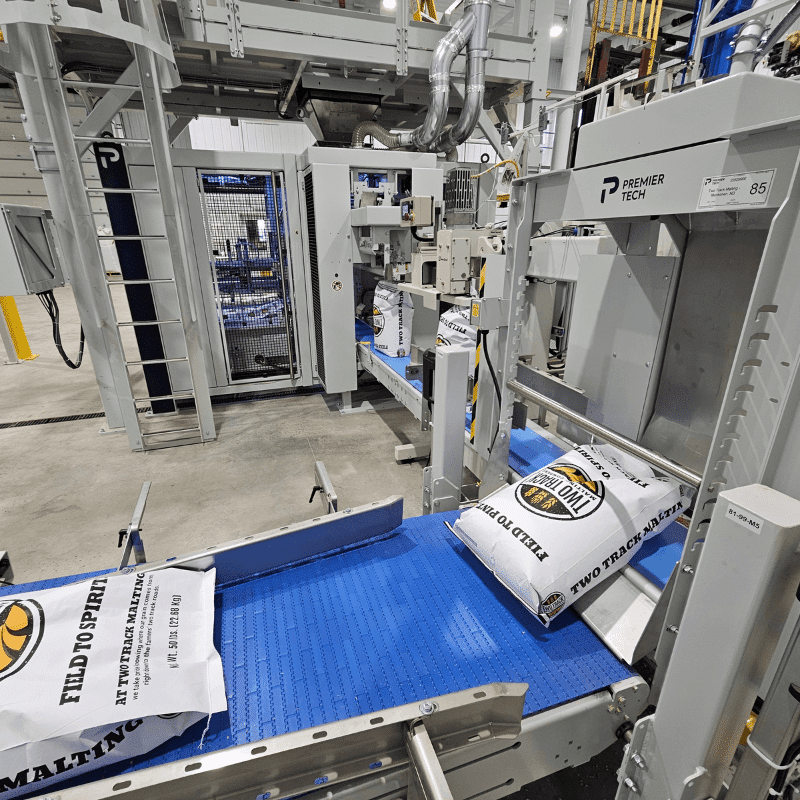

Automation

Two Track Malting partnered with Premier Tech for our packaging line. Premier Tech’s expertise in automated packaging allows us to reduce the labor needed for the hardest job at the malting plant which is filling and stacking bags. This system allows us to maintain the consistency we strive for on malted products to have the same consistency for our packaged products. The automation allows for a safe working environment so our team can focus on making the best possible malt for your brewery or distillery.

Custom Batches

Our malting facility allows us to cater to your specific needs. Whether you are a brewery or distillery looking for something custom-made or wanting to toll malt your own grains, we can do our best to accommodate this. We can guide you through the entire process to ensure you are getting exactly what you want.

We can accomodate sprouted grains and toll malting and toll sprouted opportunities.